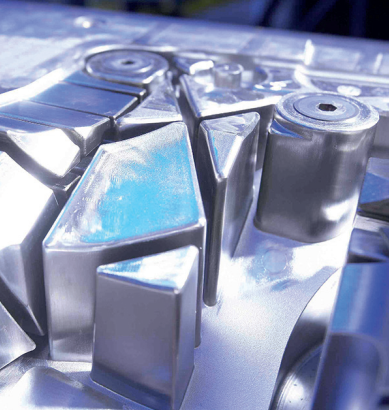

Our dedicated custom mould service is geared towards individual product development and customer-specific solutions. We offer short reaction times and high flexibility in custom tooling and the construction of tool

inserts in our company owned principal mould systems.

Protec Promould Tooling Service stands for high-quality mould construction, state-of-the-art manufacturing technologies, flexible workflows and

precise delivery service.

Protec Promould Tooling Service stands for high-quality mould construction, state-of-the-art manufacturing technologies, flexible workflows and

precise delivery service.

In-house design, state-of-the-art technology, computer-assisted development tools, quick data exchange, rapid prototyping, fast delivery times and low fixed prices are all features of the new Promould High Efficiency concept of our Protec formula for tailor-made tool solutions.

In addition to Protec Promould Tool Services such as product development, mould construction, prototyping and toolmaking - Protec Custom Moulding Service also includes services such as assembly, picking, packing, container management and shipping logistics - all under one roof.

Time is money. This is particularly crucial if projects must be realized

within short time frames. Protec Time Saver is based upon our unique

Protec master mould system. It is designed to use  Protec master moulds

for special customized inserts to save money, time and trouble through

lower tool costs and shorter lead times. This also applies complex

injection moulds up to 7000g plastic injection product weight per part.

Protec master moulds

for special customized inserts to save money, time and trouble through

lower tool costs and shorter lead times. This also applies complex

injection moulds up to 7000g plastic injection product weight per part.

Protec Time Saver is the unique technical and economical approach to considerably reduce toolmaking costs. Benefit from our efficient manufacturing methods for economic individual solutions and take advantage of our competitive low price strategy.

We would be happy to manufacture our standard items in many alternative materials, in heat-resistant versions or in specific colours by special request. Order-based and affordable.

Individual solutions also mean that we can manufacture custom design in the volume that you require for your unique purpose. You can always rely on our precise, made-to order-production.

PROTEC meets the most stringent demands of safety and operations reliability. International approvals and certifications such as UL, CSA, VDE, VDA 6.1 and DIN EN ISO 9001: 2015 demonstrate total quality commitment on superior level.